You may order the publication at Burg Giebichenstein Halle or our This email address is being protected from spambots. You need JavaScript enabled to view it..

Throwing away, recycling, or questioning this system? Some products live forever, are even passed on from generation to generation. Others have a short life, are not used a second time and end up as garbage instead. Only rarely an equivalent product emerges from them. But is a long life always the better one? Are there applications and situations where disposable products are more sensible, more sustainable and even better than durable products? We made it our task to develop deliberately short-life usage concepts, which are still, or precisely for this reason, sustainable. With external partners, we compared concepts, materials, services and application scenarios and assessed them with regard to their sustainability. We developed new conceptions and sensible scenarios that are surprising –not just because they are designed to be discarded. Mareike Gast

A FAN - Designing a sustainable fan // dispose

a FAN

© Lukas Unertl (Burg Giebichenstein Kunsthochschule Halle, Germany)

» This is a fan – well designed, functional and good looking. But is it sustainable?

I tried everything to create the perfect solution for a fan. I changed material painting techniques and improved the efficiency grade. I tried alternative technologies and turned the fan into a modular system, where every component is accessible to the user and can be replaced if needed. That was already quite an improvement. Yet, I thought the fan still wasn’t a sustainable product. I removed unnecessary parts like the pole and the main electronics. That solution allowed me to install the fan with a regular E27 light bulb socket, but that was not enough. I turned the fan into a collapsible object. During the cold winter months, when any fan becomes an obsolete object, this one can be reduced in size. Textile is placed on top. Once blown up it turns into a light emitting surface. Wow! I got it. I finally turned a seasonal everyday object into one that can be used the entire year. However, the fan still wasn’t really a sustainable product.

So, I suffered the summer temperatures without a fan. I ended up sleepless and sweating away for an entire season. No, that wasn’t the best idea. So, what is the perfect sustainable fan? I think it doesn’t exist. There is always a hitch. When you buy your next electronic device, think twice, buy it smart.

DOWNHILL – A sledge of ice and snow

Downhill

© Martha Sophie Kikowatz (Burg Giebichenstein Kunsthochschule Halle, Germany)

» From the idea of shortening the lifespan of a sledge to its actual service time, two solutions emerged. The use of ice and snow limits the existence of the products to the time and place of use.

The sledge made of ice:

Fill the reusable moulds with water. Add fir needles to the water for reinforcement (e.g. from a Christmas tree). Put the moulds in the freezer. When it is cold enough outside, assemble the individual parts and connect them with water. After sledging, the sledge can be left behind at the end of the slope.

The sleigh bag:

The sleigh bagis perfect for a hike in the snow. It can be carried up the mountain almost unnoticed in a pocket. At the top, it is unfolded and filled with snow. At the end of the track, the bag is emptied and fits back into the pocket.

LIVING LIGHT - A hand full of light // dispose

LivingLight

© Jonas Jentsch (Burg Giebichenstein Kunsthochschule Halle, Germany)

» Imagine a light without a bulb or fixture; a light that does not need fire or electricity. A light that can’t burn or destroy; a light that doesn’t need switching on or off. A light that grows. A light that lives.

What would change if the development of luminescent bacteria was so advanced that they could complement or even substitute our ordinary lighting? If they could be grown not only in laboratories by specialists but by everybody at home? If we could use them whenever and wherever we want, take them with us or spray them without fear of doing any harm?

In what way would our relationship to the use of light change, if it was a living organism cared for by ourselves instead of this technical thing? Would the rate of light pollution grow as steadily as it does at the moment? Or, is it possible to start a change in the way we deal with light?

MONOSCALE - A a monomaterial approach // dispose

Monoscale

© Marcel Bohr (Burg Giebichenstein Kunsthochschule Halle, Germany)

» We want to own and consume without limits. But what approach prevents products such as electronic devices from having a large ecological footprint?

One possibility is to replace electronics with a monomaterial that replaces electronic functions by material-immanent properties. This is how the idea of a kitchen scale was developed.

The shape of monoscaleallows the residual stress of the material to be used as a measure: The more the scale is loaded, the more it deforms, which is indicated on the scale in grams. The material used is PETG, a polyethylene terephthalate (PET) modified with glycol, which is characterised by high viscosity and impact strength. It can be bent at any angle without breaking. Also, it complies with food safety standards to be used in the kitchen. The monoscalecan be produced by injection moulding. This allows it to be manufactured in a single piece in a very cost-efficient way.

MUDBUD - A clean way to play with dirt // dispose

MudBud

© Netta Nahardiya (Burg Giebichenstein Kunsthochschule Halle, Germany)

» There are many qualities to mud for children other than being advantageous to the immune system. It encourages creation and imagination, develops the brain, and more. Many kids these days don’t get to play with mud. The main reason is that mud is outside and the outside might be full of unpleasant dirt. As parents, we want to keep our kids safe, or “clean”, we would rather buy the “clean” brand new plastic car toy than let our kids play with dirt. MudBudis dirt that suits parents.

POSE – A wedding dress grown of mycelium // dispose

Pose

© Sophie Thurner (Burg Giebichenstein Kunsthochschule Halle, Germany)

» Weddings have a big impact on our natural environment. From the many guests, who travel to the location, over large quantities of food, to loud music, the rings and the wedding dress. Considering the fact that often the dress is used for just one day and then spends a life time in a closet, I propose a concept for a disposable wedding dress. The dress is made of mycelium –the “roots“of fungi –a highly sustainable, fast-growing material. It does not require many resources and can be harvested almost everywhere without infringing on the space we need for growing food.

Aside from the obvious economic benefits, the dress is perfect for the latest trend, the post-wedding photoshoot, at which you are likely going to destroy the dress, but have great wedding pictures in return. The mycelium dress comes with special effects, for example, it could glow in the dark, it could lose some patches when in water, creating a new pattern, or include the bloom of flowers as the dress comes into contact with water. After a photoshoot in a lake or in the sea the dress can’t be used again, but that’s alright. The wedding is over and there are breath-taking pictures as a memory. These added extras in combination with the fact that the dress is grown only for oneself give the garment a tremendous personal attachment.

SOAK - Printing body fluid // dispose

Soak

© Fabian Hütter (Burg Giebichenstein Kunsthochschule Halle, Germany)

» The concept of soakfeatures a way to eliminate the effort and the negative environmental effect of printing by letting the product print itself during the course of use.

The first idea deals with a children’s plaster: The flowing blood is used to “print” the image of a dolphin just by using a blind pressed padding. Blood, that usually has an unpleasant character, is transformed into having a positive, surprising and thereby cheering effect.

The same principle is transferred to a sports shirt: While doing sports sweat can be used to “print” a logo on one’s shirt. This effect not only motivates to sweat more, it is also more sustainable. A combination of two different cellulose fibres allows for this effect. The resulting monomaterial shirt can be easily recycled in comparison to those with prints.

TOTOGO - Toast that needs no toaster

ToToGo

© Julia Ernst (Burg Giebichenstein Kunsthochschule Halle, Germany)

» Do we need to rethink sustainability?

Some facts: Thin and small foil packaging is not being recycled. Neither is the packaging of toast. After use, it is transported by a truck to a waste incineration plant, where it is burned in order to at least regain the energy from that foil. At the same time, we plug in a toaster at home to toast the toast. The toaster is made of an enormous amount of precious materials, which are processed in a such way that hinders recycling and it uses electrical energy when toasting.

So, what if we use the energy of the packaging directly and burn it on the table and thereby toast the toast? Why not save all the hassle, materials and transportation?

This proposition is truly possible – by using PE, a common packaging plastic, that burns without toxic by-products. From an environmental point of view this concept makes sense:According to the MIPS1concept the estimated environmental impact potential of a toaster toasting 100 toasts is about 60 times bigger than for 100 ToToGo toasts. (considering thematerialinputs for the production of thetoaster, the used energy to toast the 100 toasts, the packaging and the transportation of the toaster and the packaging of 100 toasts – not including the toasts themselves.)

What does this venture mean for us as consumers, for the toaster industry and for our general perception of sustainability?

VACUUM - Temporary objects // dispose

Vacuum

© Johannes Voelchert (Burg Giebichenstein Kunsthochschule Halle, Germany)

» The technique of creating a vacuum allows the construction of temporary objects in a sustainable way. The different filling materials are non-permanently bonded together since the stability is created solely by the evacuation of air. Thereby the use of new material is minimised. As filling materials, even ever-present ordinary objects can be used, which reduces the amount of new materials needed. Due to the non-permanent connection, the components are fully separable. The foil is recyclable and the filling material is even reusable.

Different use-cases are demonstrated.

VERBLASST - Information with an expiry date // dispose

Verblasst

© Valena Ammon & Edda Rabold (Burg Giebichenstein Kunsthochschule Halle, Germany)

» Verblasst is a speculative concept that focuses on temporary information within the context of advertising in public space. It plays with the idea of generating information through the medium of light. The focus is on surfaces which are coated with photochromic pigments. As a result, advertisements and offers can be projected onto these surfaces. The exposed areas change their colour – like exposed photographic paper. Yet, after some time the information vanishes again. The surface is ready to be exposed again.

To formulate our concept, we asked two questions: What if the fading could be slowed down and the information vanished after one day or one week? What if we could adjust the kind of light the pigments react to? Both are not yet possible with standard photochromic pigments but technically not impossible.

Production processes often follow straight value chains. This results in unwanted side streams and by-products – mostly waste products. We set ourselves the task of finding extraordinary, surprising, perhaps bizarre, but in any case, valuable, industrial waste streams and used them as a starting point – as raw materials for a new material, a new product, a system that works circularly instead of linearly. The project focused on the explorative and experimental examination of diverse materials and their further processing as well as the networking of different industries and processes for the development of sustainable product and business concepts. With the support of external partners, concepts, materials, services and application scenarios for waste materials were developed that cross-link and circulate. In the course of the discussion, manifestos arose which take a clear stand on the subject of sustainability. Mareike Gast

BAKER'S BUTCHERY – From industrial bread remains to mealworm protein // reuse

Baker‘s Butchery

© Lukas Keller (Burg Giebichenstein Kunsthochschule Halle, Germany)

» The concept Baker’s Butcherydeals with the integration of a mealworm farm into a bakery, in which the overproduced bakery products get converted into protein. The integration leads to an efficient use of resources, due to multiple uses of infrastructure. The concept shows possibilities and advantages of a future in which insects are established as foodstuffs. It should help to question the existing food culture and production, which is a determining factor for global warming and the waste of resources. The Baker Chips are the communication medium and a possibility to approach insect consumption. The chips contain 85% wheat bread remains, 5% mealworm flour and 10% beetroot. The beetroot is responsible for the red colour but more importantly for the right moisture ratio to make a processable dough.)

All calculations are based on an existing bakery taken as an example.

GARNET SAND 3+ - Tiles and vessels // reuse

Garnet Sand 3+

© Tian Pan (Burg Giebichenstein Kunsthochschule Halle, Germany)

» How can we use the large amount of shapeless waste sands, containing different particles of the cutting materials, which come from a normal water jet cutting factory? Through experiments with porcelain, glass and the simulation of the sinking process I found out that those waste sands could be suitable in the porcelain industry. It can be added to the traditional porcelain-making process to make everyday vessels. Another characteristic of this mixture is the anti-slip property, which is very well suited as an additive in tiles for floors in sanitary areas. On walls, the metallic property can be used as a magnetic pinboard.

MATEREALISE – materials from reused cotton fibres // reuse

Materealise

© Ulrike Silz (Burg Giebichenstein Kunsthochschule Halle, Germany)

» The project materialise aims to tackle the negative impact of the textile industry by reusing and recycling cotton fibres from production waste streams. It is time to realise that those fibres are a valuable material source and that adequate recycling systems need to be initiated. New technologies can convert the waste into materials like fibreboards, fleeces and cords. The possibilities in their handling and aesthetic potential are shown in a collection of experimental samples and material combinations. The application in seasonal fashion is exemplified by simple shoe components.

MEMBRANE– three possible applications // reuse

Membrane

© Fabian Hütter (Burg Giebichenstein Kunsthochschule Halle, Germany)

» 1.4 trillion poultryeggs are produced annually, according to the Food and Agriculture Organization of the United Nations (FAO). This corresponds to about 1.5 million tons of egg membrane. In the industrial context, the egg shells and membranes are used for cement production, but only the calcium carbonate (lime) of the egg shell is utilised. The glycoprotein egg membranes simply burn away. In order to save the valuable membranes, I developed a procedure to separate them from the shells. In the following I illustrate the potential of this material with three possible applications.

Spray Packaging:

The egg membrane encloses the egg white and protects it from microorganisms. We owe the long durability of eggs to the membrane. Its reuse as food packaging is therefore more than conclusive. With the help of sodium hydroxide, the protein chains can be dissolved and sprayed onto e.g. vegetables directly.

Shortlife Fashion:

The dried membrane not only has an interesting material property for packaging, it also has a special aesthetic. If one covers a surface with it in the wet state, the membranes adhere to each other after they dry and create a kind of non-woven textile – a textile with a very special symbolism – especially striking for a wedding dress.

Compostable Plastic:

By compression moulding the egg membrane without any adhesive agents, the proteins link to a compostable bioplastic – a translucent material that is an alternative to fossil-based plastics.

SECOND SKIN - 3D printing or moulding with by-products of the leather industry // reuse

Second Skin

© Jakob Müller (Burg Giebichenstein Kunsthochschule Halle, Germany)

» Second Skin is a material study that deals with the unused parts of skin in the tanning industry. Excess skin and its valuable ingredients usually stay unused and are disposed of. By chopping and homogenising the skin pieces, a viscous mass is produced. This can be shaped by 3D printing or injection moulding. The gluing properties of the skin create a sturdy, flexible material, which can be optimised for various applications with the aid of enzymes. These enzymes, such as transglutaminase, create cross-links within or between the proteins of the skin – similar to the tanning process of leather.

YOUR HAIR - YOUR INK -– Coloured ink made from your own hair // reuse

Your hair - Your ink

© Leopold Seiler (Burg Giebichenstein Kunsthochschule Halle, Germany)

» Our hair is unique and individual. It reveals who we are, stores habits and indicates our age. An ink from one’s own hair reveals personal uniqueness to the user and puts the great diversity that exists in hair into a different context – by making it tangible. A signature with this ink reveals more than just the name. It verifies itself unmistakably and every handwritten sentence contains a very personal quality. The personal relationship to the ink underlines the gesture of writing.

In cooperation with the Institute of Biochemistry of the Martin-Luther-University Halle, Germany, I have enzymatically dissolved various hairs, obtained pigments from them and then transferred these into ink.

Hardly any material creates as great of an ambivalence in us as plastic. On the one hand, it is perceived as cheap, short-lived and environmentally unfriendly – and it is used that way. On the other hand, plastics and their processing methods have decidedly shaped our consumer goods and thus our everyday life, because plastic is an extremely multifaceted, malleable and at the same time affordable material. At the same time, plastic is future-oriented: it is potentially produced from alternative raw materials, is in principle very easy to recycle and, with growing importance, is replacing rare materials in order to produce functional, for example, electronic components. In this project we devoted ourselves to the super normals, the simple, everyday, almost invisible commodities made of plastic, examined their necessity – also from a cultural perspective – and developed a next generation. A key aspect lies in the recyclability and use and design of material cycles. During the semester, we went through the entire design and development process right up to mass production in injection moulding from recycled plastics. For this we used the Precious Plastic Machines by Dave Hakkens. Mareike Gast

CYCLOGON - A minimalistic repairable pedal // recycle

Cyclogon

by Simon Krautheim (Burg Giebichenstein Kunsthochschule Halle, Germany); Photo: Martin Patze

» The bicycle is one of the most sustainable means of transport, but the way people interact with it and its design sometimes is lavish and material-intensive. My design of a bicycle pedal made of recycled plastic is a response to this: The modest octagonal platform is produced from high density polyethylene (HDPE) utilising the do-it-yourself (DIY) injection moulding machine by Dave Hakkens and screwed onto an axle using only two standard cartridge ball bearings and one nut. All parts can be replaced in minutes without special tools. Therefore, they can be recycled separately. The plans for the pedal will be open source – just like the DIY injection moulding machine – and will empower cyclists to repair and design their bicycles themselves.

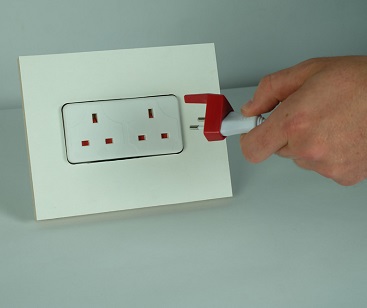

EURODAPTER – The sustainable adapter // recycle

Eurodapter

by Fritz Rahne (Burg Giebichenstein Kunsthochschule Halle, Germany); Photo: Martin Patze

» The power socket is an everyday object that could not be more common. There are different variants worldwide for basically the same plug. This leads to overproduction of a large number of products. Anyone traveling, for example, from Germany to England must purchase an adapter for their electronic devices. Due to the combination of different materials, these are very difficult to recycle. The Eurodapter saves resources, is made of a monomaterial and, nowadays, is sufficient for practically every device that a traveller carries with him or her.

HANG ON – A washer hook // recycle

Hang On

by Jasmin Schauer (Burg Giebichenstein Kunsthochschule Halle, Germany); Photo: Martin Patze

» Hang On gives the washer a completely new function: It is a conical hook attached under visible screws. Areas of application can be found everywhere: in the living room, on kitchen cabinets, shelves or shelf supports. Hang On consists of reused polyethylene, from which most bottle caps are made. These can easily be collected in a wide variety of colours and integrated into the new material cycle. It can be melted down many times without loss of quality in order to produce new products.

HISCA – Opens a bottle easily // recycle

Hisca

by Hannah Kannenberg (Burg Giebichenstein Kunsthochschule Halle, Germany); Photo: Martin Patze

» Opening a water bottle is an everyday activity that you only become aware of when it becomes a problem. Thanks to its handy shape, HISCA (lat. “start opening!”) offers a simple solution due to its powerful leverage. A real relief for anyone who lacks strength in their hands.

The screw cap is material-saving and designed for mass production by injection moulding. As with conventional bottle caps, the HISCAbottle caps are recycled by returning the bottle together with the cap to the deposit system. During the recycling process, the cap material polypropylene/high density polyethylen (PP/HDPE) is separated from the polyethylene terephthalate (PET) of the bottles and can be reused in its pure form for production.

For its convincing inclusive design, this project was awarded with the first price of the Hessian State Award for Universal Design 2018 in the category ‘young talent’.

LÄUFT - She pees standing // recycle

Läuft

© Nele Meier (Burg Giebichenstein Kunsthochschule Halle, Germany)

» Dirty train toilets, smelly Dixis, two-hour traffic jams and I just can’t hold it anymore. Every woman knows the feeling of needing to go but not being able to. Urination devices do already exist but unfortunately these are often too big to fit in any pocket discretely. On the other hand, single use products made of plastic-coated paper create unnecessary waste. I took a closer look and realised that with a length of just 13cm of recycled plastic you can create a product that fits in any pocket, is safe during use (no drops on your feet) and can be used over and over again.

MONO SIWTCH - Recyclable cord switch // recycle

Mono Switch

by Max Gruber (Burg Giebichenstein Kunsthochschule Halle, Germany); Photo: Martin Patze

» The idea was to design a switch that works without additional metallic elements. Specially shaped metal plates provide electric conductivity in conventional switches. It requires a large effort to remove these metal plates from their plastic housings. This reduces recyclability significantly. The proposed design uses the metal of the cables to close the circuit. Consequently, no additional metal is needed for the switch to function. After removal of the cables this switch may be recycled without any problems.

Of course, the switch is just a pin in the haystack. It does not solve the general problem of electronics’ bad recyclability. Yet, mono switch makes a statement – it shows it is worth trying.

NICER RICER – A measuring cup that can be used to wash rice // recycle

Nicer ricer

by Yang Ni (Burg Giebichenstein Kunsthochschule Halle, Germany); Photo: Martin Patze

» Although rice from the supermarket is flawless and packaged, rice grains are washed before preparation. This hygienic procedure from ancient times is still a spiritual act of purification. But there is no suitable utensil for washing and water consumption is correspondingly high. In order to give new life to the original tradition, the Nicer Ricer finds a contemporary approach: the classic measuring cup, as known from every rice cooker, also serves as a tool for washing rice.

RESUS - Recycled and recyclable glasses // recycle

Resus

© Sophia Reißenweber (Burg Giebichenstein Kunsthochschule Halle, Germany)

» Glasses combine a medical tool with a fashionable accessory that enhances the wearer’s recognition value and underlines his or her uniqueness. In comparison to other plastic glasses, which are mostly made of cellulose acetate, Resus is made of recycled polypropylene which, at the same time, guarantees complete recyclability. The spectacles hinges are integrated without any use of metal making it easy to put leg and frame together without any tools. The unique marbled aesthetic of the recycled material, which results from manual injection moulding, conveys a sustainable fashion statement and turns an everyday product into an individual object of value.

SCHO - The truly recyclable toothbrush // recycle

Scho

by Alexia von Salomon (Burg Giebichenstein Kunsthochschule Halle, Germany); Photo: Martin Patze

» Normal toothbrushes are made of three different plastics and are therefore not recyclable. A toothbrush should be used for no longer than three months. As the toothbrush scho is a monomaterial product, it enables the consumer to recycle it easily. The handle and bristles of this toothbrush consist of one and the same material: polyamide. It is about creating a circular economy, which focuses on reusing the resulting waste. In the designed circle of scho, a toothbrush is recycled to a toothbrush.

U.SHAVE - Sustainable shaving for everyone // recycle

U.Shave

by Irmela Krach (Burg Giebichenstein Kunsthochschule Halle, Germany); Photo: Martin Patze

» Unlike conventional razors, which are made of different thermoplastics and elastomers and that can no longer be recycled, U.Shave is made of the recyclable monomaterial polypropylene. It fits the standardized single-blade, which is recyclable as well, and has advantages like the reduction of skin irritations and no blockage of the blade by hair. Since the single blade is not connected to the plastic, the whole razor head is not replaced when a new blade is needed, but the blade is replaced.

As U stands for unisex, the U.Shave razor sets an example against the gender clichés of the shaving industry.