SME Perspectives - Interview with Sebastian Daus on Circular Design

Sebastian is co-founder & CEO at FixFirst. He used to help in his father's handicraft business in the electrical sector and learned about the challenge of dealing with repairs. After studying industrial engineering, technology management and digital innovation he gained the experience in the startup and tech industry at various stations from Uber to Rocket Internet and digital consulting. His mission now is to accelerate the shift to a circular world with scalable solutions.

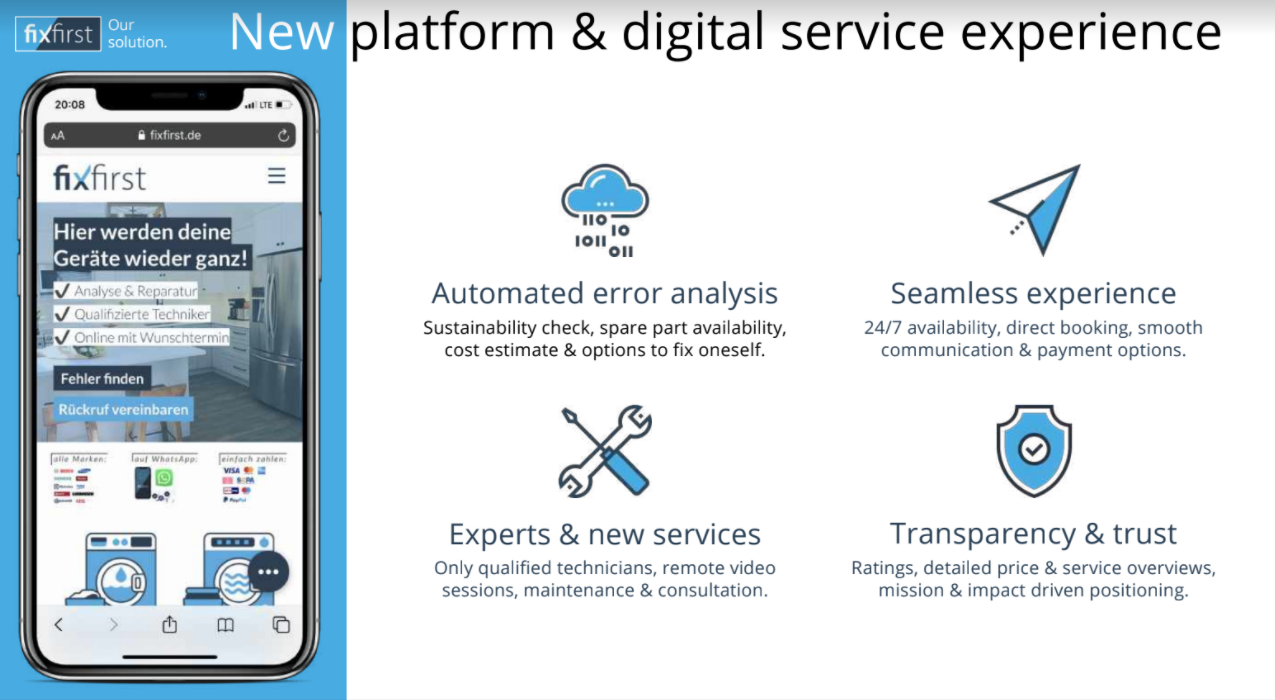

FixFirst is a Berlin-based impact and tech startup that aims to accelerate the transformation towards a circular economy. The team digitises and simplifies circular services and processes with their self-developed software platform - starting with repair and maintenance in the electronics sector. This can be used by various stakeholders - including small service and craft businesses, as well as manufacturers and retailers, or even cities. At the same time, the solution empowers companies and users to use products longer and to improve their circularity as easily as possible and to make this impact visible. "Our vision is a world where repairing products first and using them longer is the norm."

“In a world of climate emergency, population growth and resource scarcity, we'll need

to use our products smarter than ever before. Prolonging their lifetime is the key for that.”

Sebastian Daus | © FixFirst

What should motivate companies that have not yet focused on circularity and sustainability to adapt their business model and become „circular"?

The first question for me is of course: Why not yet? The beauty of both topics is that, in addition to sustainability, you can also have an economic advantage, for example in new business models that allow you to get to know your customers better and offer new services. However, it sometimes takes a lot of courage and the willingness to change - at least if you want to profit from it early on. Otherwise, the competition will do it at some point or you will be forced to do it by regulation - but only then adapting the business model and hoping that it will work is not a situation you want to enter voluntarily. From discussions with companies and experts, we know that one moment can become a barrier - the moment when you realise how interconnected and complex the topics can become. Once arrived, however, the moment can also turn around and you ask yourself "Why haven't we always done it this way?". For example, no one in Germany questions that drinking water should be clean - so why shouldn't our products and their environmental impact be the same? Another argument is timing: sustainability, customer expectations, regulation, digitalization, competition and more... the list of topics to have the right timing for is long - no wonder, then, that experts of the renowned market research institute Gartner predict that in the next 10 years the circular economy will be the only economy, replacing linear economics.

Implementing EcoDesign & circular solutions in a company may seem daunting. It is often associated with a lot of effort and high costs. What do you

say to skeptical entrepreneurs?

Quite often I think: "What is the alternative?" - Continuing to buy time and pushing everything onto the next generations? Staying in the comfort zone and continuing to climb your own career ladder risk-free for the next 2 - 4 years and leaving everything to someone else with the next position? That is an exaggerated description of course - as an entrepreneur with a background in business and engineering, I understand that it's not that simple and especially products with complex supply chains can't be changed just like that. However, I believe that change starts in one’s mind and requires a certain openness and curiosity: As a leader, do I want to be a role model and try new approaches myself? Also in my role as end user?

Now to our approach: In discussions with customers, we can usually quickly prove that, in addition to sustainability goals, we can also present a business case, thus affecting classic KPIs such as cost savings or customer satisfaction. Of course, it always depends on the individual case - but there are now enough positive examples so that companies can also tackle such challenges together or at least learn from others.

What are the biggest and most common problems holding companies back from introducing circular products so far?

In fact, we often see different levels of knowledge about circularity. You might hear something like "We're good at that - we already do waste separation!". Sometimes there is no one who is responsible for those topics. It can then happen that such a project is started in a marketing department and later peters out because other departments would have to be involved, but there are different interests. When things get going, they quickly get bogged down in complexity - similar to large initiatives in the area of digitisation that also involve a business model innovation. Another issue is thinking too closely within one’s own boundaries - for example, with packaging: We can now make packaging more circular - but do we perhaps still need it at all? As a packaging manufacturer, you have to think further ahead in order not to end up like a print magazine, for example, that has not switched to online. Often, a new business model can also emerge from an existing waste stream. The pressure to change is also often unspoken - as long as you have your cash cows in your portfolio, you naturally want to continue to keep them. To actively promote the disruption of your own business model, you need a bit more strategic foresight. This certainly applies primarily to manufacturing companies - but also to their suppliers and service partners who have to adapt to the changes.

FixFirst developed a software platform to simplify circular offers | Slide taken from an online presentation in Sept 2020 | © FixFirst

How can these problems be solved or circumvented?

Personally, I think that the topic must first be placed much higher on the agenda. For the implementation to succeed, it needs to be anchored in the vision as well as clear strategies and goals that can carry the transformation and new ideas towards it. When it comes to implementation, it's all about the details. An example from our practice: A strategic pillar of the circular economy is to use products longer and to offer circular services such as repairs. For this to work operationally, you usually need service partners. If more products are to be repaired or refurbished in the future, the inspection and logistics process must become more efficient. It would then also make most sense to offer those services from a single source and combine them, for example, with a product-as-a-service model. This then changes the incentives to offer such services over a longer period of time, so that principles such as Design for Circularity are more likely to be taken into account. For this, in turn, you need knowledge and transparency about what actually happens throughout the lifecycle of a product and a way to integrate existing networks and cooperation partners - here, of course, software platforms like ours can help - but you have to start with your own vision.

What are the first three steps a company can take to become more sustainable?

I think the quickest place to start for oneself are the internal processes - from energy consumption to business travel and electronics. If you internalise and exemplify the issues, it's easier to apply them to your own products and services and run less risk of greenwashing. Of course, you have to ask yourself whether you have the right skills and the right partners in your portfolio - innovation programs can also help here. But it is also important to measure the right numbers, e.g. in terms of the expected impact - such as lifecycle analyses of products or impact assessments of the entire company. I find it most inspiring when a company not only participates in this transformation because it has to, but also actively shapes it, taking an entire industry and its partners with it.

FixFirst ran a competition in Jan 2022: social media users could post their oldest piece of functioning electronic equipment.

This is a washing machine from the times of your grandparents. Or your great grandparents? | © FixFirst

What are the three most important lessons you have learned on your way to circularity? What do you want to pass on to others?

As a founder, I clearly stick to the startup wording: Build, Measure, Learn - in other words, work agilely and quickly in small steps, try out ideas and quickly learn what works. In addition, openness to new ideas and collaborations coupled with a pinch of courage and urgency help. I think it is an inevitable change - sustainable is the new digital - but without circularity it won't work! Last but not least, I see this as a team sport - only this game is about our future... the players are all of us with a good chance of winning - albeit against the clock. So, the game remains exciting!

The interview was taken by Berlin Institute for Innovation.

Download the interview as pdf.